Plastic Injection Molding

Our Services

Why choose us for plastic injection molding?

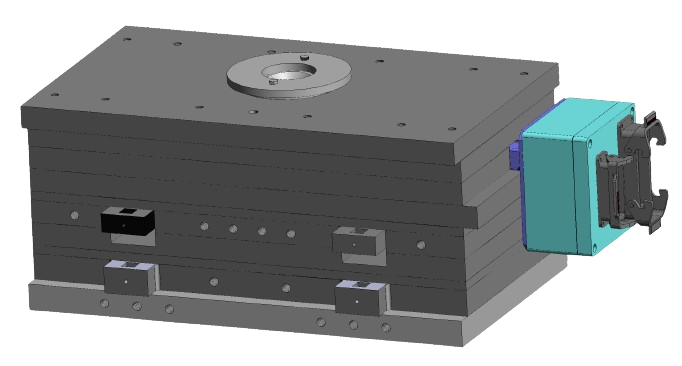

The technical specifications of the plastic injection molding press we have are:

- Force: 450 tons

- Maximum Injection Volume: 1960 cm³

- Thermoregulators for the Fixed and Movable Parts of the Mold

- Built-in Controller for 12 Hot Nozzles

- Dryer for Raw Material / Plastic Pellets

- Maximum Size of Resulting Plastic Part: 700 mm * 700 mm * 700 mm

What is the plastic injection molding press used for?

The plastic injection molding press is used to produce large quantities of plastic parts in various industries, including the automotive, aerospace, medical, and consumer goods industries.

Injection-molded parts are made by melting plastic pellets and injecting them into the mold cavity. This creates the desired shape of the plastic part, which is then cooled and ejected from the mold.

Our company manufactures plastic parts using the client's mold, but it is also possible that the mold is manufactured according to the customer specifications.

Completed Orders

Plastic Pavers 600 x 600 x 50mm